When it comes to workplace safety, having an effective first aid strategy is non-negotiable. Ensuring that you can provide critical first aid quickly in the event of an emergency. However, this can only be achieved through well-structured workplace practices, with clear procedures and a strategy in place to maintain safety. Below are five key things to consider as a workplace first aider to build and maintain a strong first aid strategy:

1. Process and Procedures

The first and one of the most vital parts of your workplace first aid response is having a clear process. There must be a clear procedure in place so that once an incident has occurred, the appropriate aid can be provided as fast as possible. With staff knowing who and how to contact the nearest on-site first aiders quickly, to treat the situation immediately and gather any equipment required, such as your workplace first aid kits.

For more serious injuries where further medical assistance is required, it is important for staff to be clearly directed, either by the first responder or through following a set escalation plan. This may involve clearing the area of people and hazards, informing further medical staff and or the emergency services if required.

2. The Working Day

Frequently, organisations misjudge the different variables in the working day, with it not being uncommon for first aiders to only be present during “normal working hours”. Missing out on staff members who are active after-hours, such as cleaning staff or those working overtime. But it is crucial to consider the whole working day in its entirety, with trained first aiders covering the full range of hours your staff are present.

During quieter times, this requirement may vary, where you may only need a minimum of one appointed person present. However, this will be determined by the findings of your most recent risk assessment and the type of work completed at these times. Risk assessments also highlight any lone working or remote working practices, which would likely have a different agreement in place. These regulations apply to all workplaces, and employers must assess first aid needs based on the workforce, working hours, risk levels, alongside other factors.

3. High Risk Areas

First aiders need to be readily available at all times, and as a result, consideration should be taken for the layout and size of your workplace site. Adjusting for the varying risk levels across the site, taking extra care to target your first aid training and workplace first aid kits around high-risk areas.

For example, if you have heavy machinery, chemical storage, or a large warehouse section, the likelihood of injury is much higher than in your site’s office areas. Therefore, you should adjust your strategy around this to ensure that first aiders are on hand quickly.

4. First Aid Equipment

The contents of your workplace first aid kit/kits must be frequently maintained to ensure that they stay relevant to the risks, adequately stocked, and up to date. Scheduled maintenance can also verify your kits haven’t expired, checking that all the equipment is in working condition. The HSE guidance states that:

“Every employer should provide for each work site at least one first-aid container supplied with a sufficient quantity of first-aid materials suitable for the particular circumstances.”

The law does not give a fixed list of requirements, but guidance and standards such as the British standards – BS 8599 can help to identify suitable contents, alongside your assessment findings. If your site has unique dangers such as chemical use, burn risk or a remote location, your first aid kit should also reflect those hazards.

5. Records and Assessments

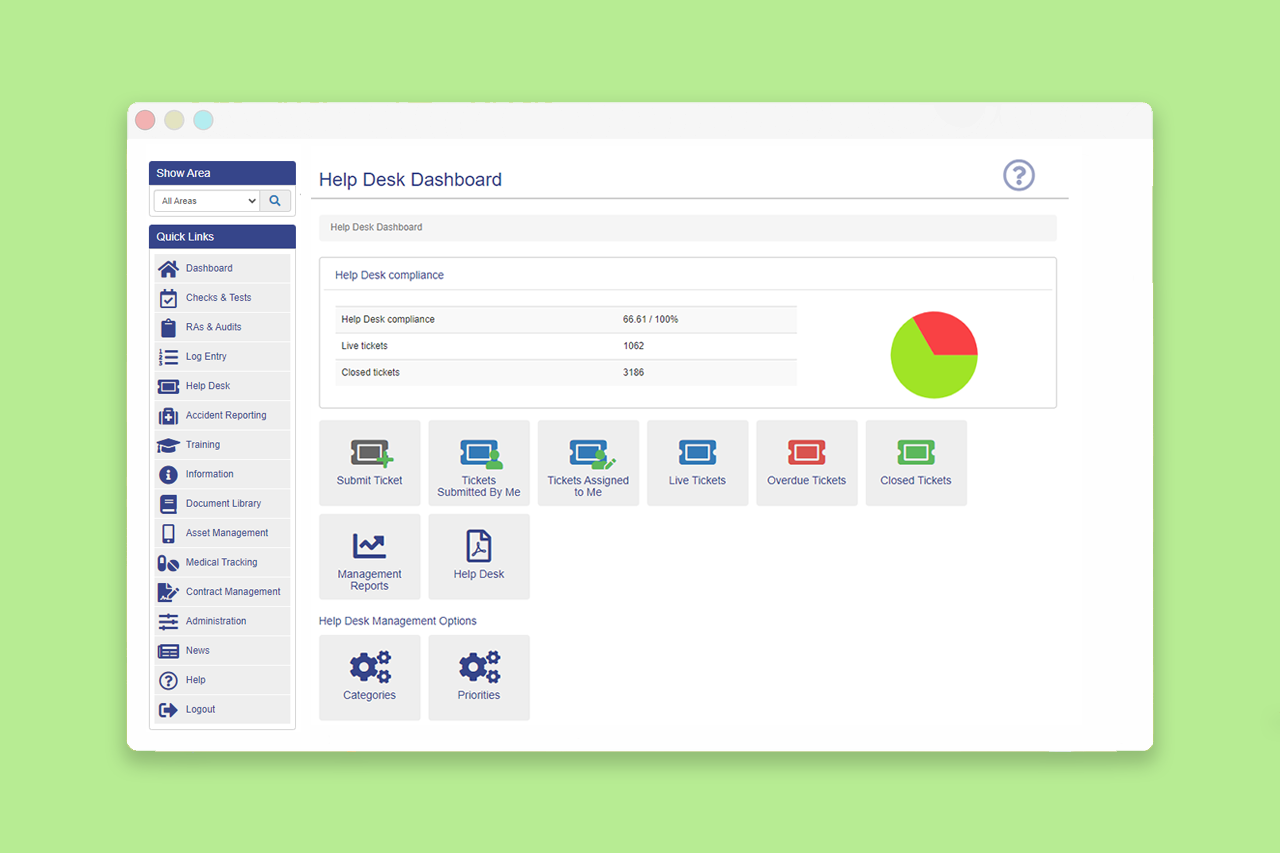

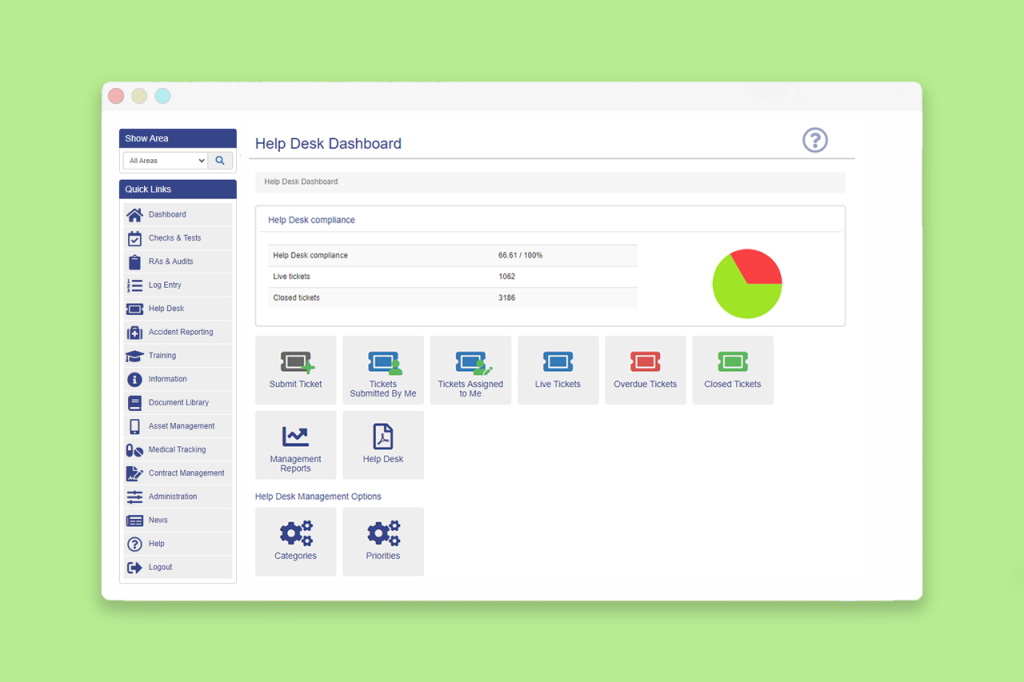

Finally, being proactive with your management is critical to preventing long-standing issues. Keeping logs and records of any maintenance, near misses or incidents is not only a legislative requirement, but also offers important insights into your workplace’s high-risk areas and trends.

Reviewing and analysing these trends can help you better target your first aid strategy, flagging the key high-risk areas and times of the day to your attention to safer protect your staff. Highlighting the importance of keeping consistent records and your knowledge up-to-date through regular refresher training.

Conclusion

The role of a workplace first aider is vital to the upkeep of your workplace safety and involves a lot more responsibility than knowing the essentials of first aid. How you structure, deliver and reflect on your plan has huge implications on your strategy’s success, with these considerations helping to format a comprehensive plan. Directly impacting much more than your first aid strategy, promoting confidence in your organisation’s health and safety culture, which has positive knock-on effects throughout your business.